Industrial Internet of Things (IIoT): Connecting Machinery and Processes

The world of technology has seen a rapid evolution in recent decades. From the invention of computers to the development of the internet, these advancements have revolutionized the way we live and work. One of the latest groundbreaking innovations in this realm is the Industrial Internet of Things (IIoT), a concept that aims to connect machinery and processes in the industrial world.

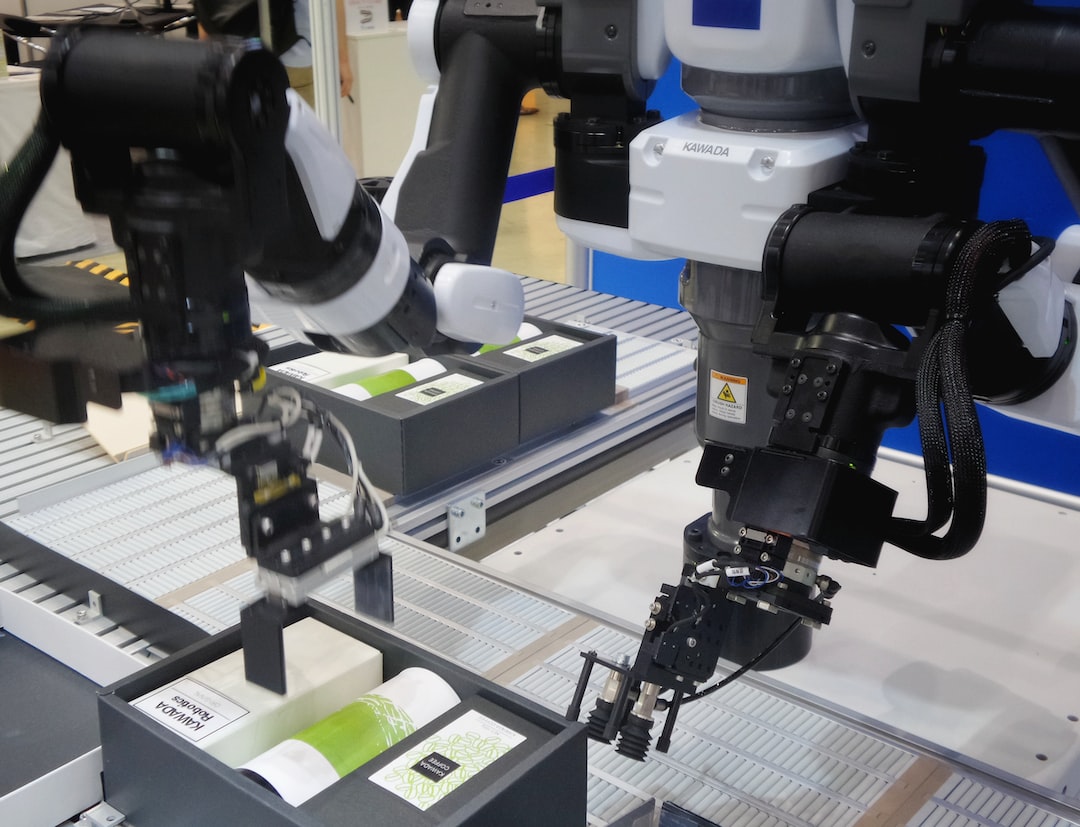

Simply put, IIoT refers to the integration of sensors, devices, and software in various industrial sectors, such as manufacturing, energy, and transportation. These interconnected technologies work together to collect, analyze, and share data, resulting in improved efficiency, productivity, and safety.

One of the key components of IIoT is the use of sensors. These small devices are embedded in machinery and equipment to gather real-time data, such as temperature, pressure, and movement. This data is then transmitted to a central platform for analysis and decision-making. For example, in a manufacturing plant, sensors can monitor the production line and detect any anomalies or malfunctions. This enables predictive maintenance, ensuring that repairs are made before a breakdown occurs, minimizing downtime and costly repairs.

Moreover, IIoT enables organizations to create a digital twin of their physical assets. A digital twin is a virtual replica of a physical object or process that allows for real-time monitoring and simulation. By creating a digital twin, companies can gain insights into the performance and behavior of their assets, enabling predictive modeling, optimization, and better decision-making. For instance, a power plant can create a digital twin of its turbines to analyze their performance and identify potential improvements in energy efficiency.

In addition to improving operational efficiency, IIoT offers numerous benefits in terms of safety and security. By connecting machinery and processes, organizations can ensure the safety of their workers by remotely monitoring and controlling potentially hazardous operations. For instance, in a chemical plant, IIoT can enable the remote monitoring of critical parameters, such as temperature and pressure, ensuring that workers are not exposed to dangerous conditions.

Furthermore, IIoT plays a crucial role in enhancing the security of industrial systems. As more devices and machinery become interconnected, the risk of cyberattacks increases. Therefore, companies need to implement robust security measures to protect their systems and data. These measures include using encryption, implementing strong access controls, and continuous monitoring for any suspicious activity. With IIoT, organizations can detect and respond to threats more effectively, safeguarding their assets and ensuring the integrity of their operations.

The potential applications of IIoT are endless. From smart cities to precision agriculture, IIoT can transform industries and revolutionize the way things are done. For example, in the transportation sector, IIoT can enable real-time monitoring of vehicles and optimize routes, reducing fuel consumption and carbon emissions. In the healthcare sector, IIoT can facilitate remote patient monitoring, connecting medical devices to a central platform and allowing healthcare professionals to monitor and analyze patient data in real-time.

However, the implementation of IIoT is not without its challenges. One of the major obstacles is the integration of legacy systems and devices, which may not be designed for connectivity. Connecting these outdated systems to the IIoT infrastructure requires careful planning and retrofitting. Moreover, the vast amount of data generated by IIoT can overwhelm existing IT infrastructure and pose challenges in data management and analysis. Therefore, organizations need to invest in scalable and robust data storage and processing capabilities.

In conclusion, the Industrial Internet of Things (IIoT) represents a significant advancement in the industrial sector, connecting machinery and processes to create a more efficient, productive, and safe working environment. By leveraging sensors, data analytics, and digital twins, IIoT provides organizations with valuable insights for better decision-making and optimization of operations. Moreover, IIoT offers enhanced safety and security measures and opens up endless possibilities for innovation and transformation. However, overcoming challenges such as legacy systems integration and data management is crucial to fully harness the potential of IIoT and take advantage of the benefits it offers.