Exploring the Role of IoT in Smart Manufacturing

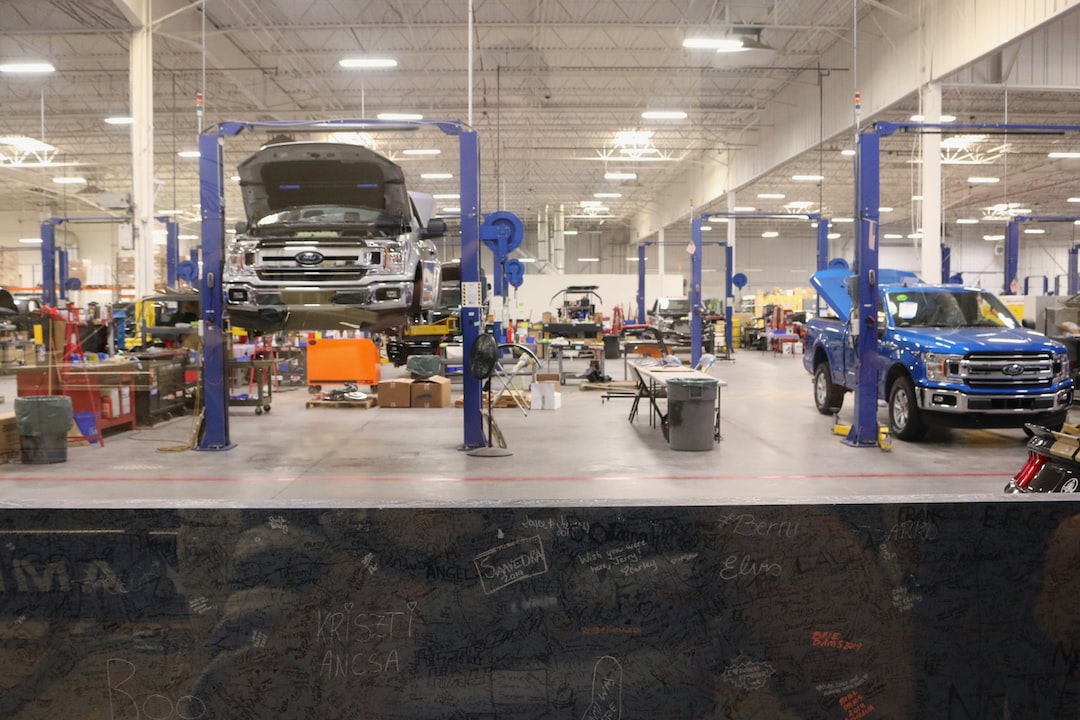

In recent years, the Internet of Things (IoT) has revolutionized industries in various ways. From smart homes to connected vehicles, IoT has brought unprecedented convenience and efficiency to our daily lives. However, one industry that has significantly benefited from IoT is manufacturing. Smart manufacturing, also known as Industry 4.0 or the Industrial Internet of Things (IIoT), is transforming traditional factories into intelligent, interconnected production systems. In this blog post, we will explore the role of IoT in smart manufacturing and how it is revolutionizing the industry.

IoT in smart manufacturing involves the integration of sensors, machines, and data analytics to create a more efficient and productive manufacturing process. Sensors are embedded in machines and equipment to collect data on various parameters such as temperature, vibration, and energy consumption. This data is then transmitted to a central system for analysis and decision-making.

One of the key benefits of IoT in smart manufacturing is predictive maintenance. By continuously monitoring the condition of machines through sensors, manufacturers can detect anomalies and potential failures before they happen. This enables them to schedule maintenance tasks proactively, avoiding costly downtime and optimizing the overall equipment effectiveness (OEE). With predictive maintenance, manufacturers can transition from reactive and scheduled maintenance to a more efficient and cost-effective approach.

Another significant role of IoT in smart manufacturing is process optimization. By analyzing real-time data from production lines, manufacturers can identify bottlenecks, inefficiencies, and potential areas for improvement. They can make data-driven decisions to optimize production processes, reduce waste, and improve overall productivity. For example, with IoT-enabled systems, manufacturers can adjust machine parameters in real-time to achieve higher quality products and minimize defects.

Furthermore, IoT in smart manufacturing enables better inventory management. By tracking raw materials and finished products in real-time, manufacturers can optimize inventory levels, reduce stockouts, and minimize holding costs. IoT sensors can be used to measure inventory levels, monitor expiration dates, and even automate the ordering process. By having accurate and up-to-date inventory data, manufacturers can control costs and improve supply chain management.

Quality control is also enhanced by IoT in smart manufacturing. By collecting data from sensors installed along the production line, manufacturers can continuously monitor product quality and detect deviations from desired specifications. Advanced analytics can be applied to the collected data to identify patterns, correlations, and root causes of defects. This allows manufacturers to make real-time adjustments, reduce scrap, and ensure consistent product quality.

In addition to these operational benefits, IoT in smart manufacturing can also have a positive impact on sustainability. By monitoring energy consumption in real-time, manufacturers can identify energy-intensive operations and implement energy-saving measures. This not only reduces environmental impact but also lowers operating costs. IoT can also enable better water management by monitoring water usage and detecting leaks or inefficiencies.

However, adopting IoT in smart manufacturing comes with its own set of challenges. One of the primary concerns is data security. With the amount of data being collected and transmitted across interconnected devices, manufacturers need robust cybersecurity measures to protect sensitive information from unauthorized access or cyber-attacks. Furthermore, implementing IoT solutions requires investments in infrastructure, connectivity, and sensor technology. The initial costs can be significant, and manufacturers need to carefully evaluate the return on investment (ROI) before implementation.

In conclusion, IoT is revolutionizing the manufacturing industry by enabling smarter, more efficient, and connected factories. The integration of sensors, machines, and data analytics allows for predictive maintenance, process optimization, improved inventory management, quality control, and sustainability. While there are challenges and costs associated with implementing IoT in smart manufacturing, the benefits far outweigh the initial investments. As IoT technology continues to advance, we can expect even greater innovations and efficiencies in the manufacturing sector.